uPVC Pipe

Soil and Waste (Low and High Temperature)

Pressure, Underground Drainage and Sewerage pipe

The ground of materials known as unplasticized PVC is one of

the most important developments of the last few decades as it reduces the cost

and improves the reliability of pipeline installations. The properties can be

varied by small addition of modifying agents which have definite and controlled

mechanical properties. They can e fabricated to close dimensional tolerances,

light without being fragile, rigid without being brittle.

Furthermore, these materials can be converted into pipes and fittings by very direct process of extrusion or injection molding even though these processes demand heavy elaborate machinery and very prices process.

The principal reason for the great economy of Excel Plastics pipes is not so much their cost per meter as delivered to site but rather the dramatic reduction in installation costs which can eb achieved by intelligent exploitation of their light weight, their availability in the longer lengths, their ease of joining and immunity from corrosion. These characteristics have even greater importance to engineers.

Benefits of Excel UPVC Plastics Pipes

Non-Corrosion: uPVC pipes resist corrosion caused by acid, alkalis, oils, salts, moisture inside and outside the pipes.

Fire proof: uPVC pipes will not support combustion.

Sanitary Advantage: uPVC pies are entirely non-toxic. It will not affect the taste, smell or color of water or liquid nor react with any liquid to case a precipitant.

Low Flow Loss: uPVC pipes have a mirror: smooth surface which minimize resistance and impede the build-up od deposits and corrosive scales.

Mechanical Strength: uPVC pipes have great tensile strength and yet they are flexible enough to withstand displacement in the pipeline. They will not indent or flatten under pressure.

Light Weight: uPVC pipes are incredibly light. Their specific weight is on fifth of steel pipe and this cut down transportation and installation costs.

Ease of Installation: uPVC pipes are easy to install, with a complete range of fittings, using solvent cement or rubber joints. Joints are leak proof. uPVC can be cut easily for installation.

Ease of Maintenance: uPVC pipes can be quicky repaired with a minimum cost and complication.

Irrigation Systems: Excel Plastics uPVC pipes are ideal for agricultural irrigation and sprinkler systems.

Industry: Resistant to most chemicals, Excel Plastics? uPVC have an important role to play in industrial plants. Light, corrosive and easy to assemble, they allow more complex piping work than with the steel or cast-iron pipes.

Electrical & Telecommunication Cables: Since Excel Plastics? uPVC pipes are made from an integral insulator; there is an ever-increasing demand for them as an electrical conduit. To facilitate the work, a full line of fittings is supplied.

The fittings for such pipes are made of uPVC or of conventional materials (i.e., cast iron or brass) and they meet the requirements of international specifications.

Technical Specification

Unplasticized Polyvinyl Chloride (uPVC)

Excel Plastics manufactures a range of high-quality pipes in the major international standard for cold water services in both imperial and metric dimensions. Pipes are supplied plain with integral solvent socket weld socket or integral rubber ring seal joint.

Pressure rating

The thermal working pressures are calculated to give continuous use for over 50 years. The operating pressures are for temperature at 20 °c. as temperature increases the pressure rating of the pipe decreases and appropriate de-rating factors should be applied as follows.

Working temperature | De-rating multiplayer | |

°C | °F |

|

23 | 73 | 1 |

27 | 80 | 0.88 |

32 | 90 | 0.75 |

38 | 100 | 0.62 |

43 | 110 | 0.51 |

Change in length (mm) = Original length of pipeline (m) x 0.06* maximum occurring temperature difference (k)

uPVC pipes are not recommended for operating at temperature 60°C or 140°F

Thermal Expansion

uPVC pipes expand as temperature rises but the expansion is independent of pipe dimeter. The co-efficient of linear expansion is as follows.

|

General Properties of uPVC |

Specific Gravity (g/mm2) Opacity (%) Water absorption (mg/cm2) |

L4 Less than 0.2 4 |

|

Mechanical |

Tensile Strength (mPa) Compressive Strength (kg/ cm2) Flexural Yield Strength (kg// cm2) Creep Pressure (N/ mm2) Izod Impact Strength (Notch) (KJ/m2) Durometer Hardness (shore) Surface Resistance (W) Density (gm/cc) |

45 704 - 775 563 - 1057 10 5-Mar 80 - 90 1022 1.4 -1.45

|

|

Electrical |

Die electric constant (60Hz) Die strength constant (KV/mv)

|

3.4 17 |

|

Thermal |

Coefficient of thermal conductivity (CAL/cm2/°C/cm10-4) Coefficient of linear expansion (mm/mm°Cx10-5) Specific heat (CAL /°C/g) Burn rate

|

5-Mar 18-Sep 63-82 0.25 -0.35 Self extinguishing |

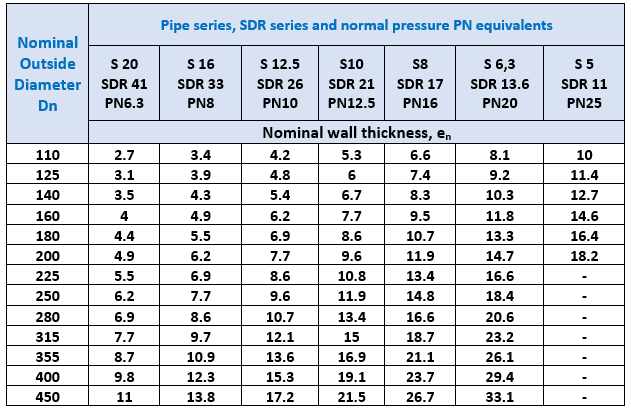

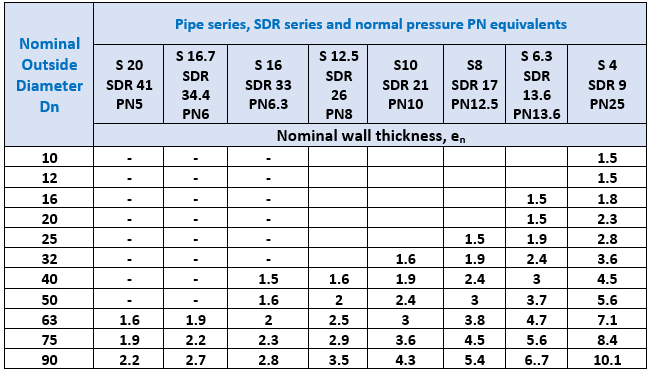

DIN 8062

ISO 161/1

|

Outside Diameter mm |

ISO 161/1 Wall Thickness |

||

|

S 20 SDR 41 PN 6.3 mm |

S 12.5 SDR 26 PN 10 mm |

S 8 SDR 17 PN 16 mm |

|

|

20 |

- |

- |

1.4 |

|

25 |

- |

- |

1.5 |

|

32 |

- |

- |

1.9 |

|

40 |

- |

1.6 |

2.4 |

|

50 |

- |

2 |

3 |

|

63 |

1.6 |

2.5 |

3.8 |

|

75 |

1.9 |

2.9 |

4.5 |

|

90 |

2.2 |

3.5 |

5.4 |

|

110 |

2.7 |

4.2 |

6.6 |

|

125 |

4 |

6.2 |

9.5 |

|

160 |

4.9 |

7.7 |

11.9 |

|

200 |

5.5 |

8.6 |

13.4 |

|

225 |

6.2 |

9.6 |

14.8 |

|

250 |

6.9 |

10.7 |

16.6 |

|

315 |

7.7 |

12.1 |

28.7 |

|

400 |

9.8 |

15.3 |

- |

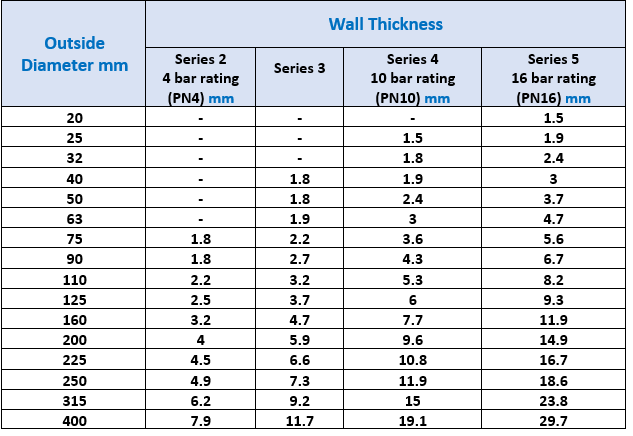

ISO 4422 - 1996

ISO 4422 - 1996