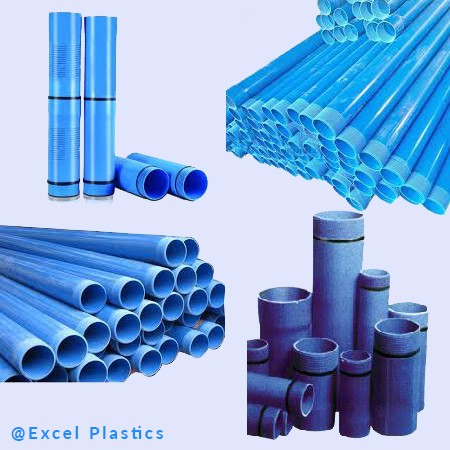

uPVC Casing

uPVC Casing & Screen Pipe for Deep, Medium and Shallow wells

Excel Plastics offers comprehensive and integrated pipe network system to serving all points and every construction in between, in every conceivable corner of the country by greening of rural villages providing rural water and sanitation network., enriching the life of poor people with affordable and effective means of tapping ground water, modernization of urban water supply, a drainage networks, and in-efficient utilization of water for agriculture and irrigation.

Excel Plastic water well casings and screens facilitate correct and economic utilization of ground water resources, incorporating the concept of water conservation, elimination of wastage without negative effect on the quality of water and ground water resource.

WELL CASING AND SCREEN

uPVC well casing and screen pipes are made compliance with the DIN 4925 standard from 1 ¼ " to 16" (36mm -400mm). A shallow depth and deep well depth range cover most applications of ground water extraction.

Excel Plastics produces high quality range of uPVC well casings and screens strictly in accordance with the metric standard DIN 4925, Part I, II, III and standard DIN 8061 foe materials and workshop of pipes used in the manufacture of the casing and screen.

Excel Plastics produces two basic ranges of standards. The first being a standard range for shallow and medium well depth and the second for a heavy duty, thick-walled range for greater well depth.

Technical Data

Material: uPVC to DIN 8061 & 4925

Lengths: Normally supplied in 3m and 6m overall length.

Slot Sizes: Available in a range of slot widths: 1.0, 1.5, 2.0, 3.0 mm

Thread style: Mechanical jointing by threaded connection to DIN 4925.

Joints: Each length is supplied with a male /female socket joint as standard, flush joints can eb supplied on the thick-walled pipe.

Marking: Standard making is a applied to all casing and screen and includes OD and T, Standard, Company's Name and Country.

Mechanical & Thermal Properties

Unplasticized polyvinylchloride (uPVC), with plasticizers and fillers.

Range of uPVC Well Casings and screens to DIN 4925

Note: Other sizes confirming to BS and ASTM standards can be supplied on request. The use of non-corroding uPVC for well casing and screen offers significant advantages over steel and other materials. The excellence properties of uPVC guarantee the maximum possible operating life of the well in many applications.

Screw Threads

All well casing and screens are provided with a male thread t the spigot end and female thread at the socket end.

Dimension and pattern

of Perforations

For every meter of filter pipe length, ten ribs up to 2 mm wider are permitted.

Key to symbols:

f approximate total effective perforations area (with a and in the middle of the tolerance zone)

Total length of perforations in one plane

h Minimum number of perforations in one plane.

Example: - given diameter of pipe = 113 x 7 mm, Slot width (w) = 1 mm

To find "f" ? See the shaded part of the above table.